Do not trust the title! Ten years ago, claims resounded that direct air capture (capturing CO2 from the atmosphere) would need only 3 times more energy than point-source capture. Everyone excited soon discovered the reality is much tougher than a good dream: the more the component you want is diluted, the more it takes to make it pure. It is like looking for a needle in a haystack – it takes energy and needs intellect.

Direct Air Capture (DAC) technologies represent an incredible feat in separation engineering: for 1 tonne of CO2, one needs to sieve a column of atmospheric air with the base of 1 m2 and the height equivalent to the distance between the southernmost and northernmost points in Germany.

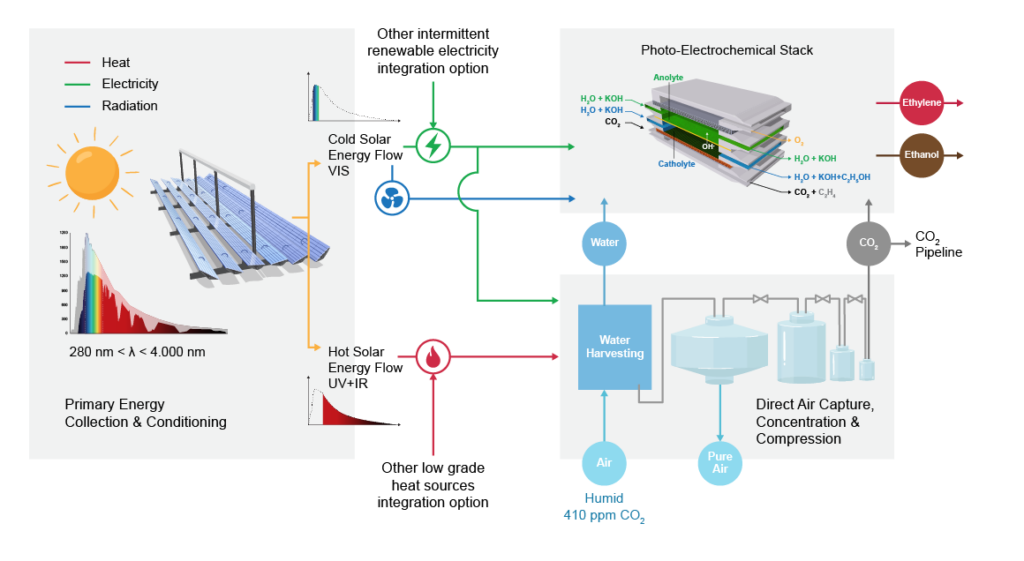

In SolDAC, we have taken the challenge on board. We know the technology we are developing will need energy, but we are using lot of intellect to make it the lowest technically possible.

We think low grade heat can help to reduce significantly the future stress on the energy system from the energy intensity of this emerging industry. In fact, DAC industry looks already intolerable for the 100% renewable energy system of 2050.

The process we are studying is mostly powered by renewable low temperature heat. Such a low quality of energy is used for heating nanoporous materials highly selective to CO2 in an unanticipated advanced purification process.

The University of St Andrews (Prof Wright’s group https://wrightgroup.wp.st-andrews.ac.uk/) is looking after the discovery of advanced direct air capture nanoporous materials while The University of Edinburgh (Dr Santori’s group) and CNR-ITAE (Dr Palomba’s group) are structuring them and arranging them in a demonstrator, along with the University of Lleida (Dr Chemisana’s group) supporting the flow distribution investigations.

The research outcomes will be presented during the 10th Heat Powered Cycles conference, 3-6 September in Edinburgh (https://heatpoweredcycles.eng.ed.ac.uk/home).